�鶹�� Offers Solution for Standard and Custom Applications

Click here to read the original article.

paperASIA: BW

Papersystems was established in June 2014 following the acquisition of E.C.H. Will, Pemco and Kugler-Womako, by MarquipWardUnited. what has the acquisition meant to your company and more importantly, to your customers?

�鶹��: Joining all these leading brands resulted in an enormous diversity – diversity of technologies, of industries supported, of team members worldwide. And with this diversity we are able to offer solutions for standard

or custom applications, for smallest converters to the largest paper mills and for folding carton plants, beer label producers and stationery manufacturer alike. Not to forget the addition of several industries for the security documents, including

passport machines.

paperASIA: How has the transition from several independent companies into one effective and efficient machinery building and customer support entity been?

�鶹��: We were independent companies, but in many case we also were competitors. Establishing �鶹�� as the umbrella company that equally combines all former independent companies was a very successful approach. The creation of global engineering, global sourcing and, not to forget, global sales and service teams naturally led to intensive international cooperation and exchange of ideas. In addition, the people-centric oriented culture, which is part of the entire Barry-Wehmiller group of companies, greatly helped to create an environment that motivates and challenges each team member every day.

paperASIA: Then in Oct 2015, Bielomatik paper processing product line from Bielomatik Leuze GmbH + Co. KG. Bielomatik operations was integrated within �鶹��. How has this acquisition further strengthened �鶹��?

�鶹��: The answer is simple: No matter what paper converting solution a customer is looking for; they will now find it within �鶹��. Especially when it comes to spare parts, upgrades and service, it’s very convenient for our customers as they get support for all of their machines – no matter if it is a Bielomatik spiral binding machine, a E.C.H. Will cut-size sheeter or a Jagenberg folio sheeter – from one source: �鶹��. The addition of Bielomatik’s paper division also further enhanced �鶹��’ global engineering collaboration and ability to provide comprehensive process knowledge and expertise in fine paper and board converting for our installations around the world. We now sell under the brand BW Bielomatik for additions to our stationery product line, and RFID for smart labels and smart tags.

paperASIA: Where does the strength of �鶹�� lie?

�鶹��: Our variety of solutions for the paper industries. Our global presence of customers in over 100 countries. Our 1,600+-team members located all over the world. �鶹�� is a sustainable and financially healthy global company that our customers can trust.

paperASIA: As one of the sources for paper mills and converters, one important aspect in the technology development of a company is its research and development programme. How active is �鶹�� in its R&D effort?

�鶹��: We value the input from all our engineers from around the world, and have several global engineering collaborations. It gives us the awesome ability to create a variety of solutions for our customers, which can be used in different regions of the world, and by different size operations. With so many talents and know-how spread at our locations worldwide, we can share the comprehensive process knowledge and expertise. For example, in fine paper and board converting, developments of new valuable solutions for our customers are well under way.

paperASIA: What are the latest technology that have been developed by �鶹��’ R&D programme?

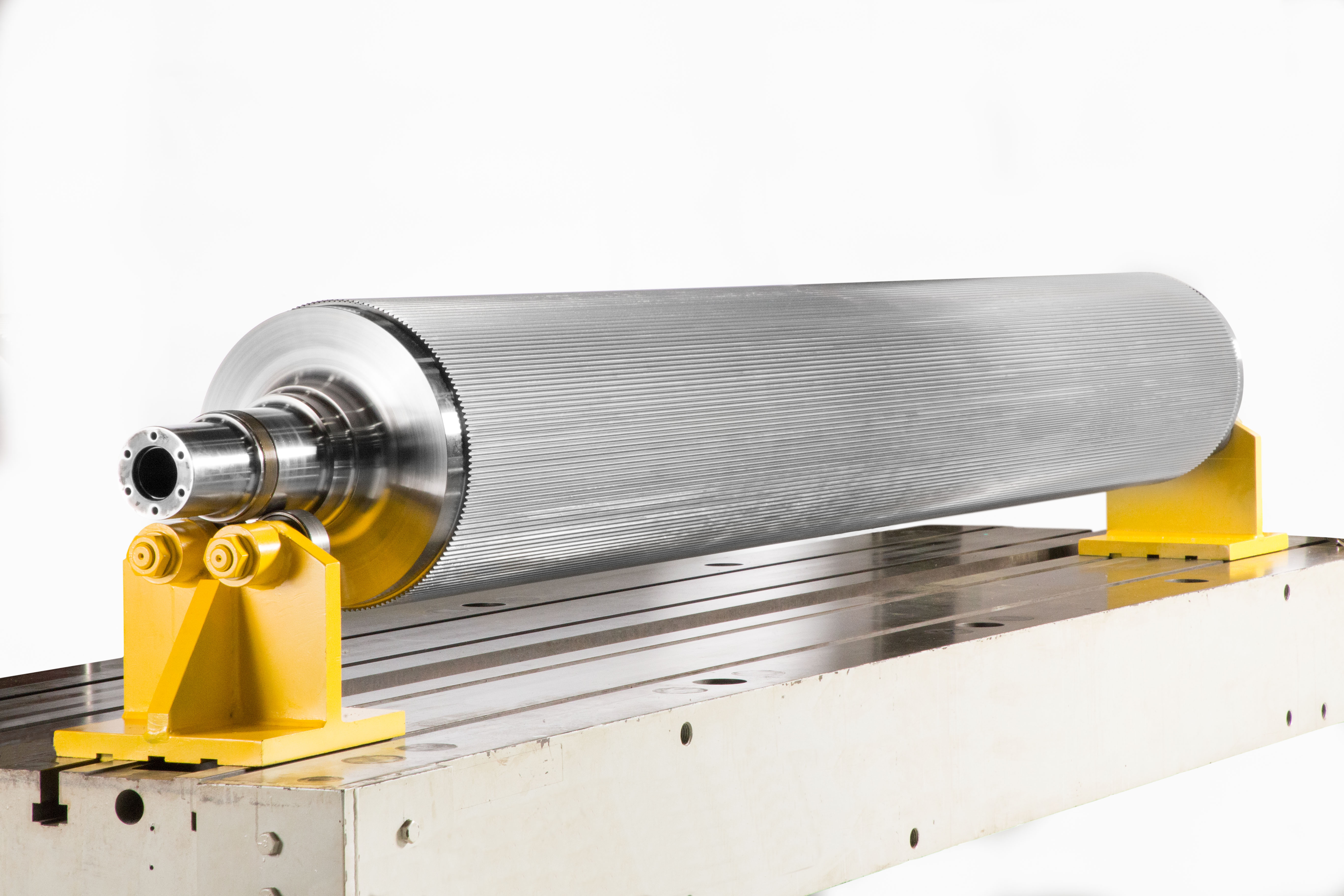

�鶹��: For sure one of the most impressive developments has been the eCon folio sheeter. Launched in 2014, it has been developed using advanced design methodologies to offer high quality twin synchronous sheeting at an extremely attractive price level. It was on display during this year’s drupa and we got a couple of orders, including from Asia. Customers were impressed by its quick ROI, its reliability and its cut quality.

PaperASIA: What are �鶹��’ latest installations?

PaperASIA: Customers’ satisfaction is also very important. How do you ensure your customer services are of the highest quality?

�鶹��: Customer Trust is at the foundation of what we do. We are committed to earning our customer’s trust by communicating to align expectations, and we have an intense focus on creating a culture of disciplined performance to satisfy our customer’s needs. Our goal is: we want to be a partner and problem solver to our customers, not only a supplier, Recently, we established our Customer Trust team that looks beyond an order, focusing on the overall customer need. In addition, with our regional service engineers and spare parts warehouses in Germany, USA, Brazil, Mexico, and Singapore and in Shanghai, we try to be as close to our customers as possible so we can support and supply them as quick as possible. And as the original suppliers of their machines, we know best what parts are needed – even for older machines and for obsolete parts.

paperASIA: �鶹�� is known globally with offices in Europe, America and Asia. How do you view the market developments in these locations? How have the developments helped �鶹�� in moving forward in these locations, particularly in Asia?

paperASIA: Lastly, what are �鶹��’ hopes for the future of the company?

�鶹��: With so many solutions for the converting of all kinds of paper and board, paper-related or other flat materials, including new technologies like the converting of RFID, we see ourselves well positioned for the future and for further growth. We hope to further intensify the partnerships with our customers, to become even more a partner, not only a supplier. Only by working together as partners, we can develop the needed solutions that allow our customers to develop new markets and to grow their businesses.

�鶹��: The European and North American markets have seen a lot of mergers in the past years. Naturally, customers buy fewer new machines. However, as �鶹��, we are able to support our customers with customised solutions – being it a turnkey machine relocation from one facility to the other; efficiency upgrades to existing productions lines; or with a jointly developed machine for entering a niche market. Asia has become our most important market. End product quality has more and more become a key factor in Asian paper mills and converting plants, so they are looking for the best technology. Our advantage: �鶹�� combines the paper and board cutting expertise from E.C.H. Will, MarquipWardUnited, Bielomatik and JAG Synchro under one roof.

Find Your Machine

�鶹�� offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the �鶹�� equipment and products offered.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)