�鶹�� Wet End

Original Article was Reprinted from the International Paperboard Magazine

Marquip, Ward, United, Curioni, Vortx and K&H are global brands brought together as �鶹��, a division of Barry- Wehmiller. It provides ‘From Starch to Finish’ solutions such as starch kitchens, complete corrugators and converting equipment. A trustworthy manufacturer focused on quality, reliability, and value for money with a strong service and parts support structure. �鶹�� manufactures several corrugator lines that range in width and speed. The Value, Harmony, Performance and Elite Corrugators ensure that the right product is available for every customer demand. Regardless of paper weight, the sheet produced must be strong, flat and have an excellent print surface for post printing and high-speed converting. To finish strong, one should start well with the VortX Starch Mixing system and the corrugator wet-ends. BW Papersystem’s philosophy views the wet-end as a single cohesive unit, but also supply individual components as needed. To optimally operate the Wet End, a supervisory system called ‘Orchestro’ is offered.

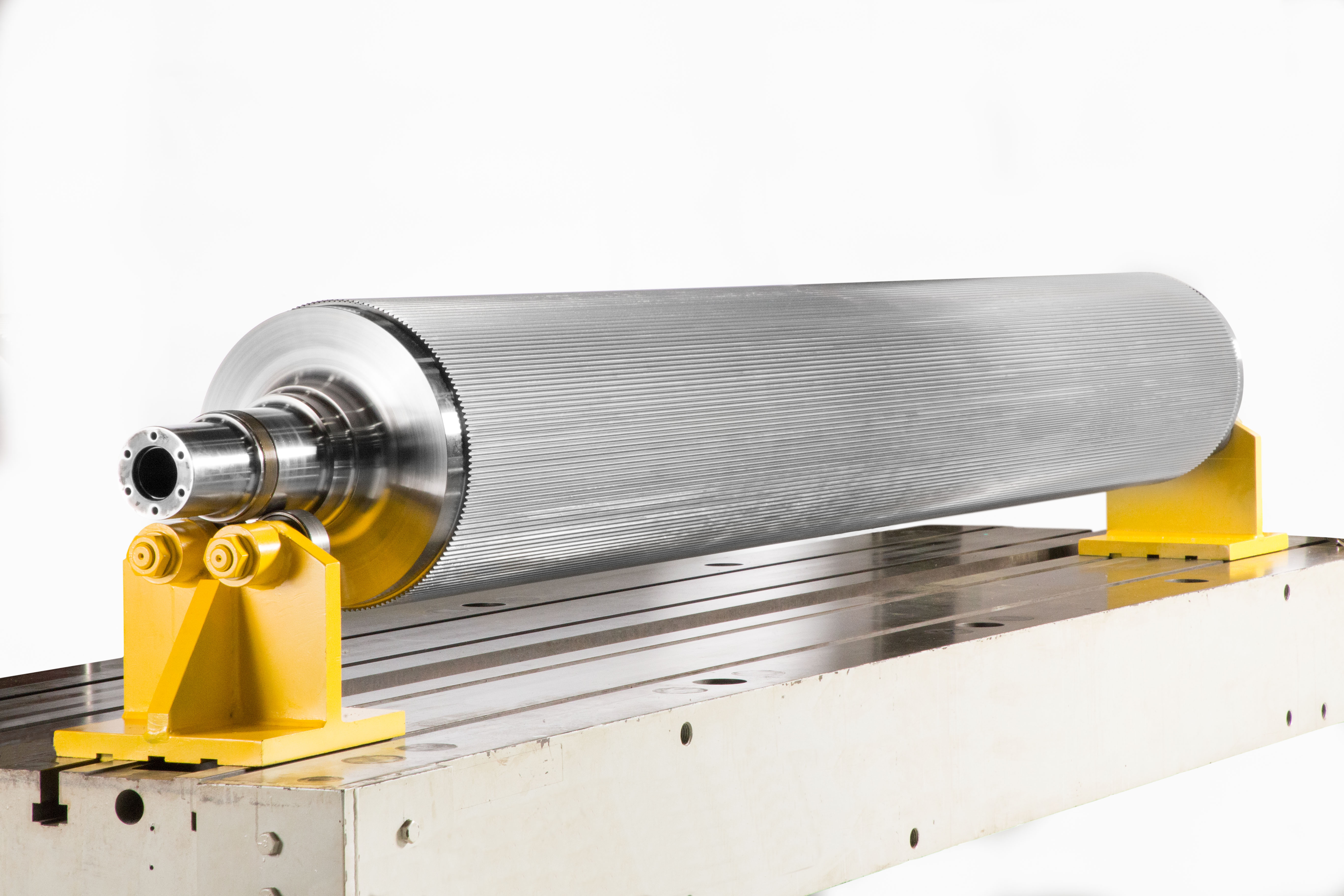

Singlefacer

The heart of the corrugator, �鶹�� singlefacers have a reputation of being robust and easy to operate. Available as pressure roll and pressure-belt, both types are positive pressure machines. Operators have indicated their clear preference

for a positive pressure machine versus negative (vacuum) pressure singlefacer. A quick flute change capability is important. Using an electric tug, all models can change a flute cassette between 5 to 10 mins. To suit an existing layout, the Singlefacer

can be configured to change from the operator or drive side. All modern options expected from a leading global supplier are available. Automatic cassette flute type detection; automatic glue dam positioning, automatic wrap arm control, metering roll

and glue application gaps are linked to the supervisory control system. To improve production, while designing the singlefacers, special attention was paid to the ease of cleaning. If a machine is difficult to clean, dirt and debris will build up

leading to inaccurate machine settings, and paper tears. The glue unit on specific models retracts 700mm to allow cleaning access for higher uptime and higher profits for the operation.

Starch Mixing Systems

When looking at starch in a modern corrugator, the parameters usually are sustainability and reducing waste. �鶹�� developed equipment to accommodate any level of demand. As corrugators get wider and faster, the entire starch production

becomes more important. Starch recipes have evolved, and now different types of starch such as wheat, pea and tapioca are used based on regional availability. �鶹�� and its partners are working on additives to reshape the starch mixing system

on the corrugator. The focus is to improve the thermal characteristics and permeability of the starch. This becomes increasingly more important with smaller flutes, and ultralightweight and recycled papers. The VortX Tornado F3 Starch System was developed

to handle higher volumes and increase the flexibility of the system. Modern corrugators use run tanks at the corrugator. This allows thermal control of the adhesive by locally adding chemicals or products on demand and within the confines of the scheduling

system. Over 300 Vortx Tornado F3 systems are installed, with customers claiming a ROI of 9 to 18 months.

Splicers and Roll Stands

�鶹�� is synonymous with the ability to splice reliably at high speed. Today’s servo tension control splicers are effective with light paper. It is not unusual to splice medium papers with a grammage of 60 to 90gsm. Modern corrugators

are run with a minimum of operators, �鶹�� designs, makes regular operations as uncomplicated as possible. Features such as, ‘Auto Index’ make splice preparation easier and quicker. The prepared splice is automatically positioned

at the correct spot for the optimum splice seal. A Mill Splice Detect option is available on some splicer models to prevent a tear out on unavoidable paper mill splices. Splice Synchronization and Bridge Buffer control are managed by the supervisory

system. Some customers place great value on an extra interface to a roll stock inventory system. The roll stand and splicer combination ensure web tension is accurate, and waste is kept to a minimum by avoiding paper breaks and ensuring simple splice

preparation. Roll Stands can be outfitted with dual size chucks giving more flexibility in the sourcing of paper. Automatic core ejection saves time for operators and reduces injury risk.

Preheaters & Preconditioning

Depending on the corrugator design speed, �鶹�� supplies 900, 1100 or 1200mm preheater drums. The drums are driven close to corrugator speed to have web tension without causing tear outs or creating end-to-end warp. Automatic wrap arm

position is controlled by the corrugator supervisory system based on the order recipe or on feedback from an optional warp measuring laser device. �鶹�� offers a remarkable paper conditioning system – ‘Infusion’ that is

fitted to a drum, a flat hotplate, or a curved hotplate. The singlefacer or outside liner is impregnated with a superheated steam that quickly boosts the paper temperature without over drying. Attempts to copy this system have met with a low level

of success. On the other hand, �鶹�� has many upgraded other name brand corrugators with Infusion hotplates at the singlefacer, glue machine or doublefacer.

Glue Machine

Glue machines can be installed as an individual machine or part of a wet-end solution. When part of a corrugator the Orchestro supervisory system controls glue gaps and glue dam settings. The glue gap settings automatically adjust to reduce glue

application as speeds increase. Regardless of micro-flute or large flute the least amount of starch is applied to ensure product defects, such as wash-boarding, warp and poor web edge bonding do not occur. Customers may choose the glue roll type and

a rider roll or contact shoe system to keep the singleface web against the glue roll with just enough contact to avoid crush and pick up just enough glue for the bond to occur.

Doublefacer

�鶹�� Cool-Vac Doublefacer combines traditional style heating sections with a Vacuum Traction Section (VTS). This vacuum pulling section reduces web crush significantly, whilst removing excess moisture from the web prior to it entering

the dry-end. Standard Doublefacers must squeeze the board to pull it forward causing a discernable level of board crush that impacts the strength of the finished box. The Cool-Vac design eliminates board crush. The Cool-Vac Doublefacer is equipped

with gun drilled (peripheral heated) hotplates, Infusion steam technology, and reliable belt tracking systems that allow lighter paper weights to be produced whilst retaining box strength. The corrugator supervisory control system interface can control

incoming steam pressures to each zone, the shoe pressure and number of shoes used per board grade and steam showers if required. �鶹�� wet-ends are flexible, reliable, and designed for most budget requirements. Customers can rely on decades

of experience and expert know-how of a group having a long heritage of supporting the industry. �鶹�� matches technology, project experience, performance, quality, and services to the unique needs of their customers.

Find Your Machine

�鶹�� offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the �鶹�� equipment and products offered.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)