Celebrating the 100th eCon Sheeter Sold

Since its introduction in 2014, the eCon Sheeter from �鶹�� has become a bestseller.

How to design a new sheeter? What does the market need? What are our customers really looking for? In 2013, a team of Product Managers and Sales Leaders at MarquipWardUnited (now �鶹��) sat down in Phillips, Wisconsin, USA, to discuss these fundamental questions.

The team’s finding: many converters and folding carton plants wanted to buy an economical sheeter from a recognized supplier with established spares parts and service network, with no compromise on cut quality or accuracy. But they also needed a simple and affordable machine which was not on the market at that time. The result: many customers bought a used machine or sourced their sheeter from small suppliers in Asia.

After interviewing potential customers all over the world, the MarquipWardUnited team prepared a very detailed specification of the new sheeter.

A completely different design approach

Until that day, all sheeter development was aimed at faster, wider, more flexible, and more efficient models. For this new sheeter, a completely different approach was chosen, using modern design and manufacturing techniques. The team knew to create a quality machine at a price the customers were asking for would require an entirely new approach with industry leading efficiencies in manufacturing, shipping and start up. The trick would be to cater to the market sweet spot and handle other more complex applications with different machine models. They believed that the aggressive cost target was indeed achievable, and the design team was challenged to complete it.

The multi-disciplined team included representatives from assembly, installation, service, shipping, and sales. During the design reviews, each section of the sheeter had to satisfy each of the involved teams before the design could be passed and put into production. Suppliers were not just asked to quote, but instead were invited to attend design reviews to advise how changes could be made to remove obstacles to efficiency. For example, a limited component catalogue was developed to ensure that, wherever possible, the same parts were used in multiple locations to reduce cost and to reduce spare parts inventory for the customer.

An economic sheeter with impressive selling point

With the design process coming to an end, it was time to name the new sheeter. The name eCon was chosen. The name reflected that this sheeter was deliberately built to be economical, but what the customer got for that investment was the impressive selling point.

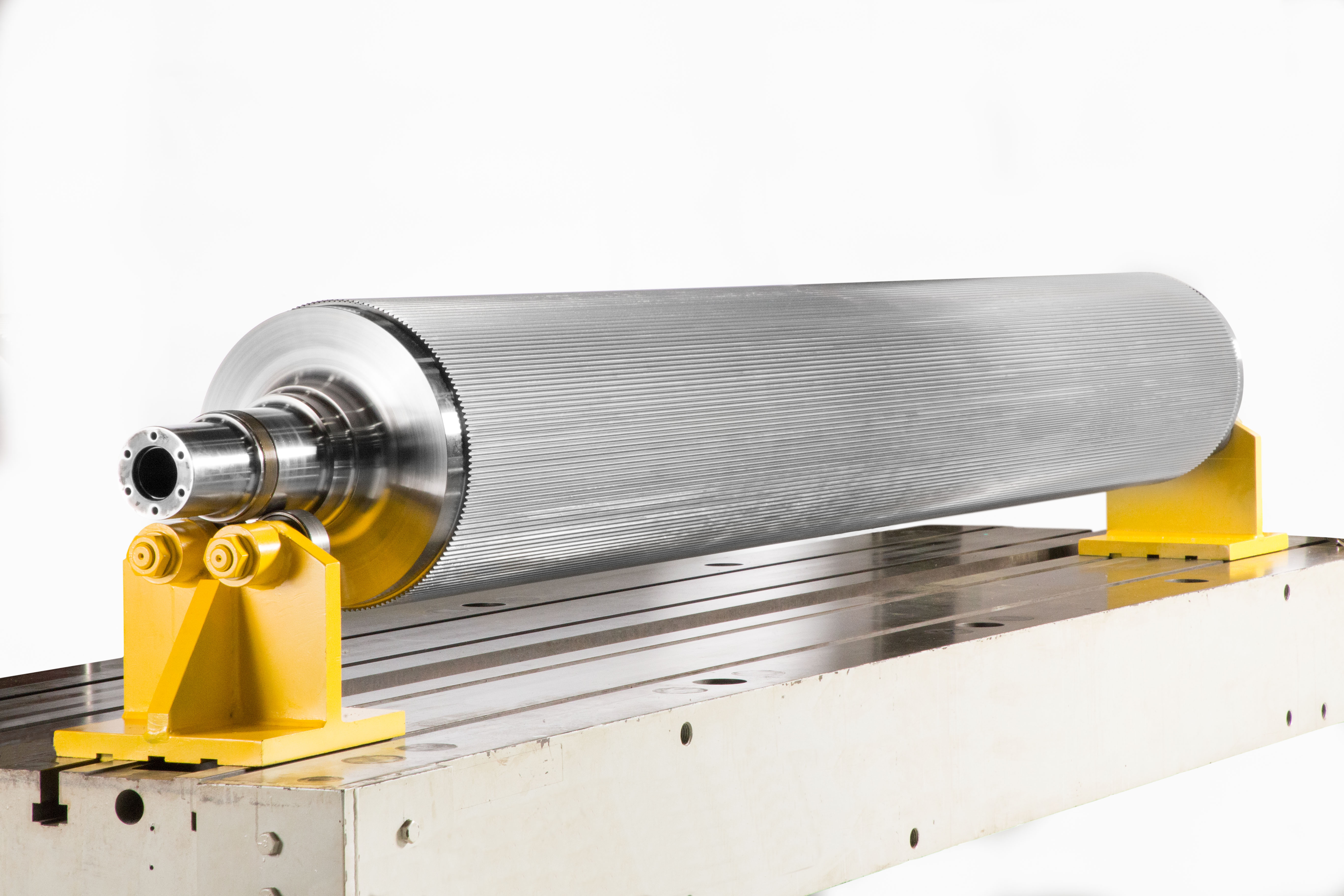

By developing a base machine with a very low number of add-on options aimed at a fixed market sector, whilst retaining proven knife technology and the same cut quality and accuracy as other more complex sheeter models, �鶹�� created a machine the market needed, at a price it could afford.

In 2014 the first machine was produced and unveiled during a multi-model Open House at the BWP headquarters in Phillips, WI, USA. During the 4 days event, customers from around the world came to see demonstrations on three sheeter models. Besides the new eCon sheeter, a mid-range SheetWizard and a 2,500mm wide fully automatic SheetPro were demonstrated.

The new eCon sheeter was the star of the event. Many converters who had shelved the idea of in-house sheeting up to then, looked at the eCon value proposition and found that the numbers added up – and so the orders came immediately.

Two years later, the eCon made its European debut at drupa 2016. Visitors to the �鶹�� booth soon realized that the cutting and stacking quality produced by the eCon was as good or even better than what they were receiving from the mill. They understood that this sheeter would allow their presses to run at maximum efficiency.

100 eCon sheeters in 8 years – and counting

Now this year, in 2022, the eCon sheeter reached the milestone of 100 units sold. 100 sheeters since 2014 means more than 12 eCon sheeters each year and more than 1 sheeter per month. 100 eCons – and counting. eCon sheeters are operating on every continent and in addition to small and medium plants, eCon has found a home at sites belonging to some of the largest manufacturers of folding cartons in the world.

A great machine, easy to operate and maintain with no compromise on sheeting quality – the eCon has become a true sheeter bestseller.

Find Your Machine

�鶹�� offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the �鶹�� equipment and products offered.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)