Lighting and Illumination: UV lighting targets passport security and adhesive inspection

Reflected UV and UV fluorescence imaging are different imaging techniques that can be used to detect features that may not be detected using longer wavelengths. In reflected UV imaging, the surface of a part is illuminated with a UV light and imaged by a UV-sensitive camera while in UV fluorescence techniques, the incident UV radiation is absorbed by the fluorescent material present in the part and is then reradiated at a longer wavelength.

Because of this, many manufacturers are increasingly taking advantage of fluorescent materials in machine vision applications for quality control, process control and testing applications. Such applications require UV lighting as the UV radiation causes fluorescent materials to glow. This glowing is clearly visible both to the human eye and to cameras. By using high-performance LED lighting in conjunction with carefully-coordinated filters, reliable solutions to a wide range of tasks and activities can be implemented.

Fluorescent, low-contrast adhesives, paints and seals can be shown in high contrast with ultraviolet radiation to make presence and completeness monitoring easier for the machine vision system. Product labelling that consumers would find distracting can also be applied with transparent, fluorescent ink. Under UV radiation, however, the labeling is easily visible for the purposes of testing. This aspect is of particular interest to the pharmaceutical industry, where product authentication and traceability are increasingly important.

Fluorescence can also be used to make even the finest cracks visible – in cast parts, for example. UV lighting equipment is now also commonly deployed for residue and residual soiling analyses, and in forensic investigations.

Another field of application is the inspection of security features and markings as protection against plagiarism and counterfeiting. iiM AG (Suhl, Germany; ) has worked with Siemens AG (Munich, Germany; ) and passport machine maker �鶹�� Stuttgart GmbH (Stuttgart, Germany; www.bwpapersystems.com) to develop a solution for this type of application. Advanced security requirements are now making passport manufacturing increasingly challenging. Here, the use of fluorescent materials has a particularly important role to play.

To ensure that these invisible security features can be reliably detected and inspected during high-speed production runs, �鶹�� Stuttgart GmbH used high-performance LUMIMAX LED lighting from iiM and 'teachable' optical readers from Siemens to develop a sophisticated testing system. The unique challenge in this project was created by the mutual 'interference' created by the juxtaposition of two fluorescent security features on a Latin American passport.

In this application, a numeric sequence printed using invisible security ink is scanned while the passport pages are being stitched together. When irradiated with UV light, however, this ink fluoresces. The sequential numbers are also printed onto a special kind of paper that has been manufactured with the inclusion of fluorescent fibres as a further, 'passive' security feature.

After in-depth testing in labs at iiM and on-site at Siemens, the scanning distance and trigger signal/flash duration timing were coordinated to ensure that the excitation of the fluorescent fibres in the paper did not prevent the scanning of the passport numbers. Despite a conveyor belt speed of 0.3 m/s during production, the enormously powerful LUMIMAX () flash lighting is easily able to create a high-contrast image without any motion blur.

Another interesting application scenario is offered by the inspection of adhesive as applied to a mass air flow sensor (MAF). While only a small component in a vehicle, the MAF can make its presence felt when it malfunctions, causing misfiring, problems with fuel intake and other performance issues. Before the mass air flow sensor is inserted into the assembly, an adhesive is applied that bonds the individual components together.

The adhesive must not only be applied in the right amount – the shape and thickness of the application must also meet precise specifications. Only then is the long-term functional capability of the sensor in the vehicle assured. To provide a solution for this task, a LUMIMAX UV Spot was used with a specially selected optical filter. This made it possible to eliminate both the light from the lighting system and the distracting light from the environment.

This solves the particular challenge with industrial machine vision and fluorescence applications – which is that the emitted light (fluorescence) has less energy than the radiation required for excitation. For the human eye, fluorescence is easily and clearly visible, but the UV radiation from the lighting system is barely detectable. However, a camera is much more sensitive in the ultraviolet spectrum. In the camera image, the UV light outshines the fluorescence from the excited material.

Accordingly, the image contrast is too low for reliable analysis. To create a viable solution for tasks such as the inspection of the adhesive applied to the MAF sensor, the specialized UV lighting system therefore needs to be supplemented with carefully coordinated lighting/lens filters. This combination filter permits the exact separation of excitation and emission wavelengths. This works to suppress interference from UV reflections and extraneous light.

As a result, the adhesive trace appears as a brightly-lit line against a uniformly dark background in the camera image. This particular solution was achieved only by the specific, individual coordination of lighting, optical filters and the component.

The UV application can now be deployed as a reliable process and error-free image analysis is now possible.

Find Your Machine

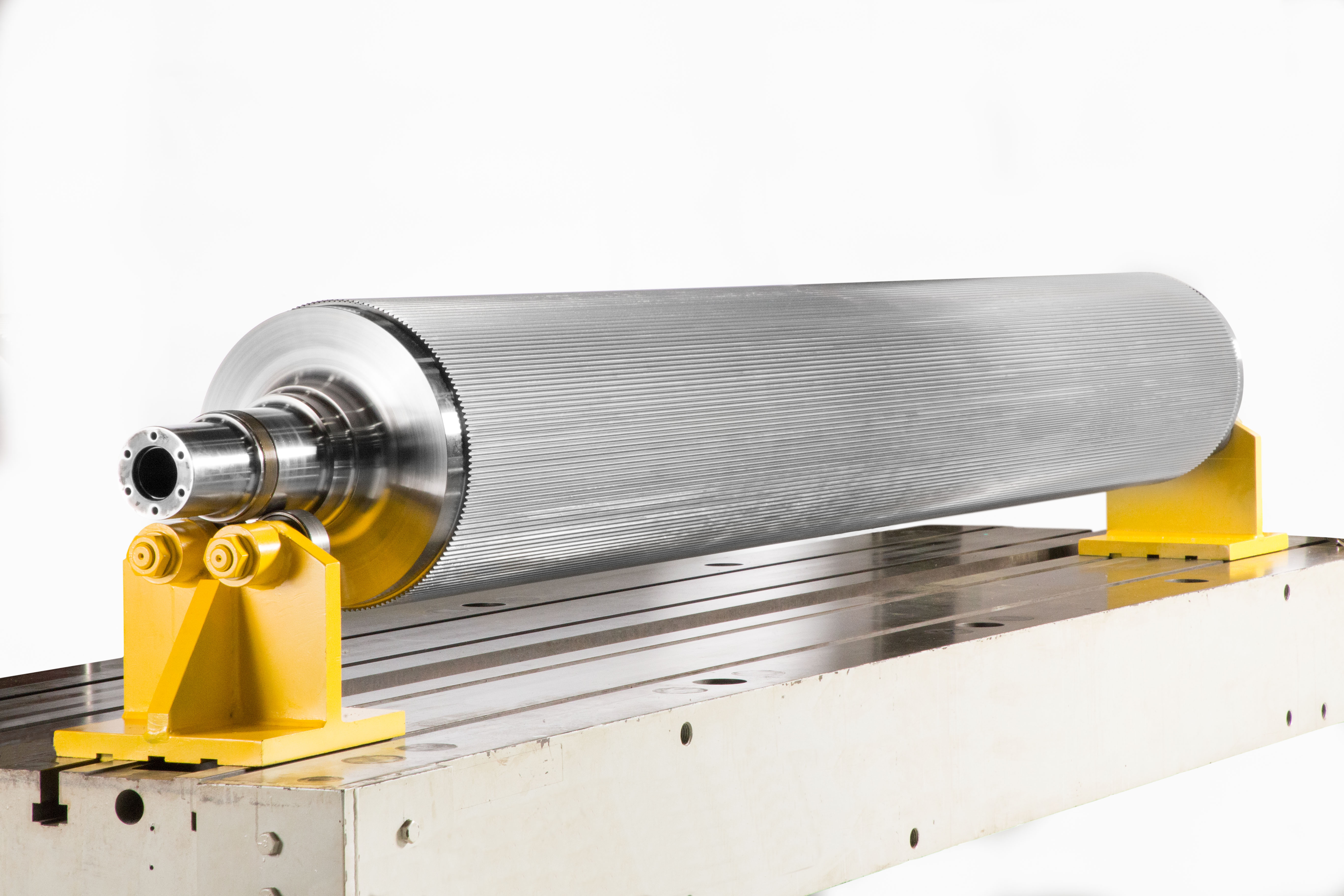

�鶹�� offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the �鶹�� equipment and products offered.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)