RAIN RFID Technology for Baggage Tracking

In an effort to handle baggage while traveling properly, at this year’s Annual General Meeting in June, decided to support the global deployment of UHF RFID technology to This decision is based on the 2018 IATA Resolution 754 defining the tracking of bags during the journey as well as the sharing of information between airlines and interline journey partners. Mainly using barcodes at the moment, airlines, airports and ground handlers are called upon in a resolution to roll out RFID bag tracking as quickly as possible. There is movement in the matter: The use of RFID technology in baggage tracking is back on the agenda. Why now?

To save mishandling costs, offer new services, optimize end-to-end baggage handling

According to , only 5.57 pieces of baggage per 1,000 passengers are lost - a decrease of more than 70 percent since 2007. Nevertheless, the costs remain in excess of US$2 billion. As passenger numbers continue to rise (expected doubling to over 8 billion in 2037), these costs, as well as the number of lost baggage items, must be further reduced. Airlines intend to offer their customers new services such as self-service bag tagging, drop-off at bag-drop stations before reaching the airport, and real-time bag tracking throughout the journey. And airports, represented by , are interested in better analyzing weak points in baggage handling in order to further optimize processes and procedures. Here is a number of reasons why RFID is an ideal choice for this.

RAIN RFID - Improved technology, lower tags costs, successful global roll-outs

The idea of using RFID tags for baggage tracking has been around for a long time. Global companies such as Siemens investigated the technical feasibility ten years ago. However, RFID tracking was not implemented due to high costs of US$1.50 per tag and standardization issues. Since then, technology and costs have improved. Low-cost RFID tags can be processed in a variety of materials, easier to write on and more efficient and secure to read. In 2016, the IATA expected just US$0.1 per bag-tag with a resulting cost saving of US₵20 per passenger. IATA members are also no longer afraid of a global rollout. Other industries (automotive, garment, food etc.) have proven that such projects are viable.

Preconditions for the successful global introduction of RAIN RFID baggage tracking

What would be the basis for a successful global deployment? Definitely a common standard for the use of RFID inlays in baggage labels. The IATA RP 1740c has been re-defined thanks to considerable Work also needs to continue on airport infrastructure, in particular RFID reader installations and the provision of Wi-Fi connectivity. The process will need to include a hybrid solution in the transition phase that allows both barcodes and RFID tags to be handled. IATA expects investments of more than one billion euros. At the same time, the saving potential is three times as high as the expenses namely US$3.8 billion over the next seven years.

- global alliance for a universal adoption of UHF RFID technology

Recent improvements in available RFID chip technology, such as increased sensitivity, encoding speed and encryption options further contribute to a highly reliable application in the airline industry. The RAIN technology not only enables real-time tracking of RFID tagged baggage, it also ensures faster inventory counts and reduced mishandling rates. A hot contender for the application of this technology comes from NXP. The company offers a broad RAIN RFID portfolio including their latest generation UCODE8, which provides speed, accuracy and security required for peak performance in airline applications.

�鶹��’ role in baggage tracking

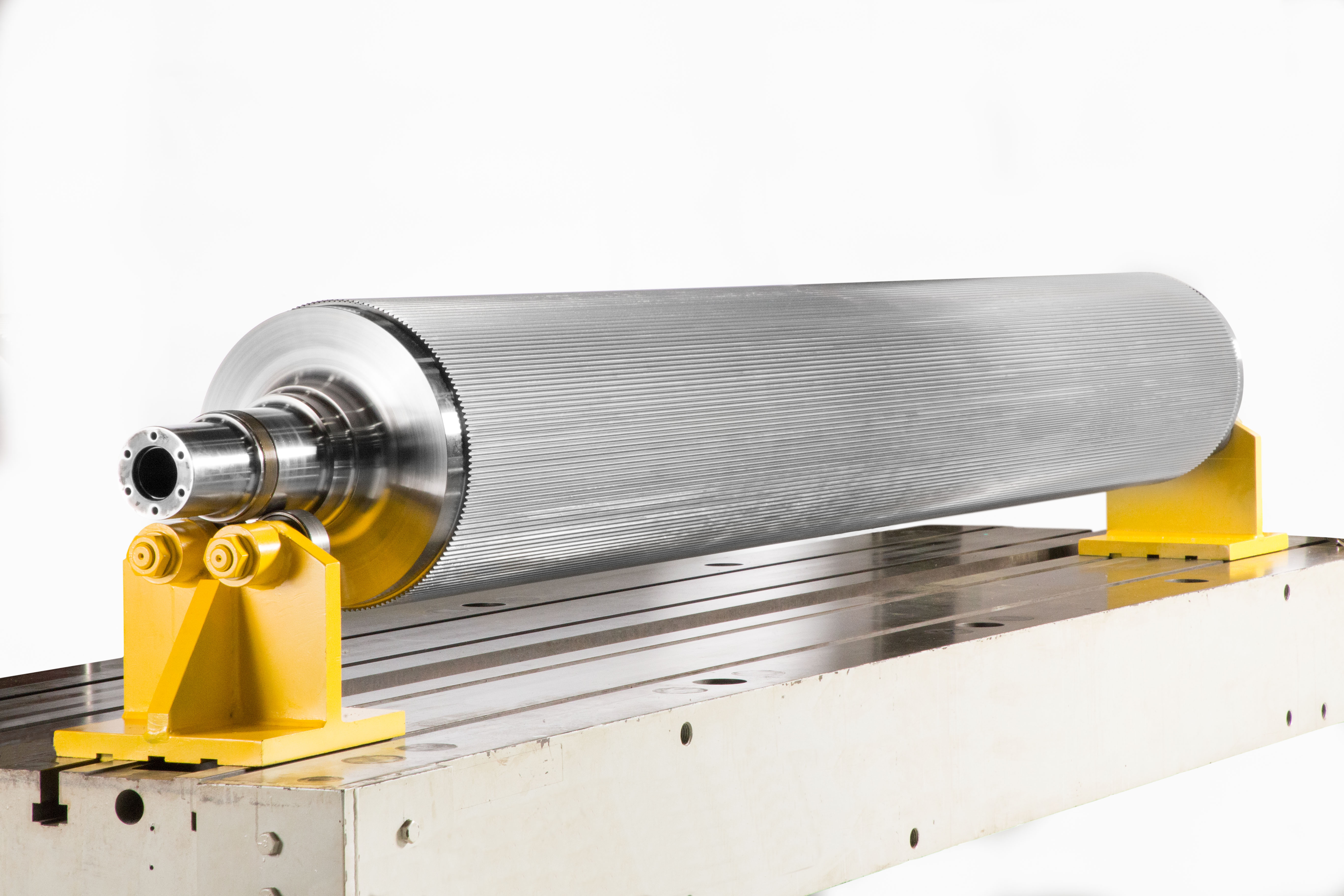

�鶹�� is a member of the global RAIN RFID alliance and is an RFID converting machine pioneer and technology leader since day one of this industry. With its latest development, the world leading TagLiner chip attach technology, �鶹�� contributes to a successful introduction of RFID solutions into the airline industry. Unrivalled mechanical bonding stability ensures survival of RFID tags under the harsh conditions which typically exist in baggage handling environments. This outstanding product quality and the TagLiner’s world-record operating speed, give �鶹��’ customers a clear competitive advantage. In addition to that, �鶹�� offers a wide range of technological solutions including multi-track converting systems, i.e. the SpeedLiner. Featuring a line speed of as high as 1.5 meters per second, the converting machine model pays off quickly as its speed capability perfectly suits the very long baggage tag format lengths. Find out more about �鶹�� solutions for an efficient and reliable production of these new baggage tags tailored to IATA’s specific requirements.

Find Your Machine

�鶹�� offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the �鶹�� equipment and products offered.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)