New Questec sheeter at DREWSEN exceeds expectations for output, size accuracy and stacking quality

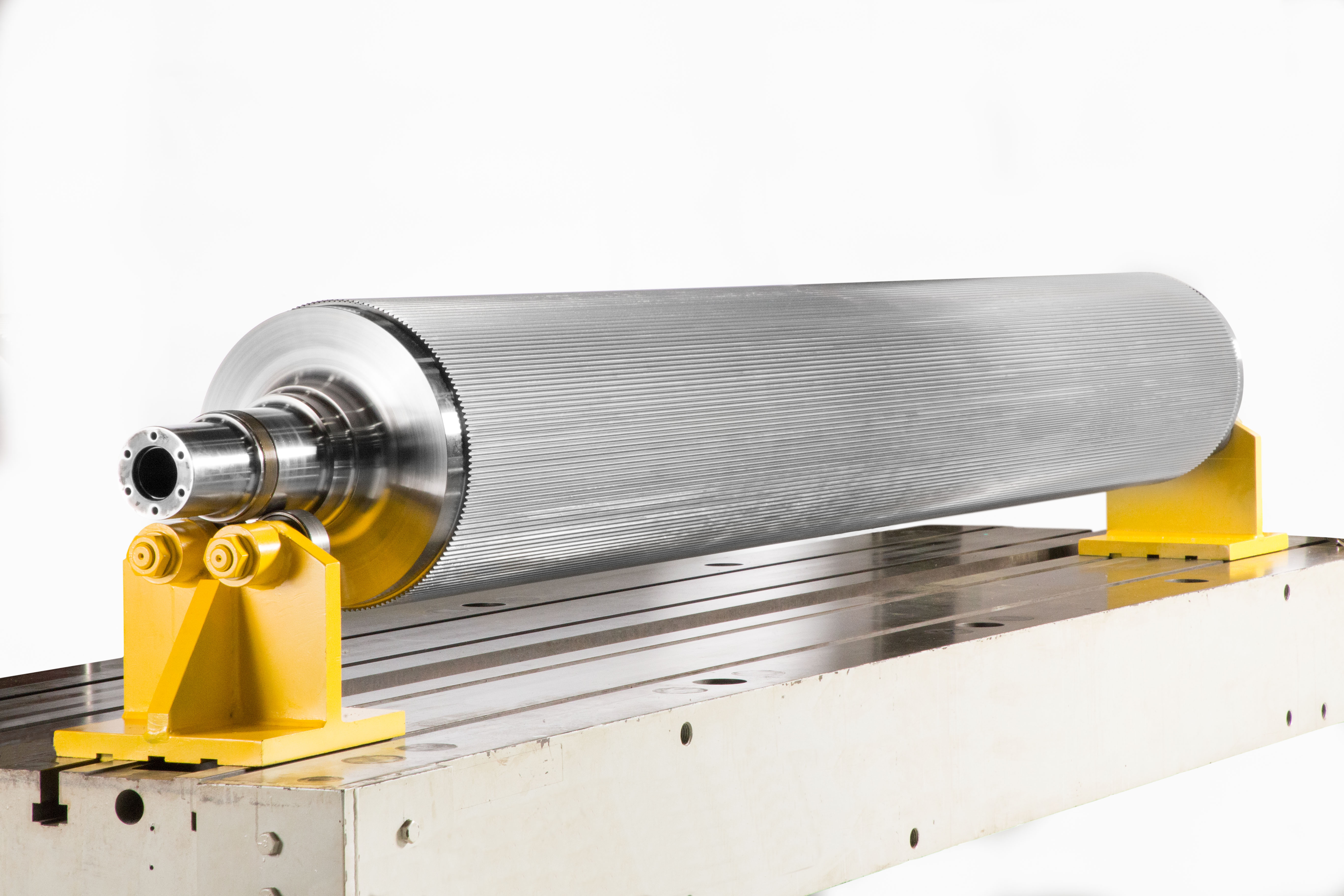

Since the beginning of 2022, a new Questec RQS-V sheeter has been added to the paper converting equipment of DREWSEN SPEZIALPAPIERE GmbH & Co. KG, based in Lachendorf near Celle. It also houses another, smaller Questec sheeter and a large SHM sheeter, both also from �鶹��. In this final interview, the third since the installation of the smaller Questec sheeter in 2021, Dr. Matthias Rauhut, CEO of DREWSEN, reports on short ramp-up curves, exceeded output volumes and excellent product quality, but also on further optimization potential and his company's consistent trend towards sustainability.

At around one ton per hour, the machine actually produces more than we expected. That is very satisfactory. And it's also stable throughout, in five-shift operation around the clock. But we shouldn't forget the quality either, it really is fantastic! The stacking quality and format accuracy are excellent, we have had no complaints from our customers, so we are also very satisfied from a quality point of view. It was important for us to maintain our high-quality level, and we can say quite clearly that we have achieved this.

In the last interview, you said that many security papers in particular had been shifted from the SHM sheeter to the Questec sheeter. Has the occupancy of your sheeters changed again as a result of the installation of the additional, wider system, and if so, how?

All security papers are now run either on the new line or on the small Questec sheeter. It makes sense that we have completely removed the security paper from the large SHM sheeter, since these papers are run in a single lane with watermark detection anyway.

What we had planned for other products was to divide larger jobs requiring a total of seven rolls between the SHM and the Questec sheeters. In other words, six rolls for the SHM and one roll for the Questec sheeter. This has not yet worked so well in practice. However, this is actually more due to the current market situation - because we are still being overrun by orders. So far, we simply haven't had the time to tackle more improvements. We were and are too busy processing orders quickly and getting them to the customer as quickly as possible. That's a pity because we clearly haven't yet reached the end of our internal improvement potential.

This is understandable. Estimating when these improvements can be addressed is probably difficult.

Correct. On the one hand, our team still needs a little more experience on the new equipment - we also have some completely new operators who have not been on the small Questec sheeter before. The more experienced the operators are, the faster the reel changeover from one grade to the next will work. On the other hand, it takes rest and time, and not this flood of orders. We are currently operating at a very high demand level, but also at a very high price level. In my estimation, this will drive the issue of digitization, so that demand will drop again. But no one can say when that will be the case. At the moment, we're not feeling any of this yet, but I expect it to happen. And then we will also have time to tackle other efficiency issues.

One of your expectations was indeed a further increase in efficiency in the equipment - 10% could already be achieved with the small Questec plant, after all.

Yes, we are clearly counting on that, because many things are simply not yet as efficient today as they could be. What we can say, however - and this is again a compliment to �鶹�� - is that our expectations for output with the large Questec sheeter have been exceeded by 10%. Our target was 900 kg per hour, and we actually achieve 1000 kg. On many days, the sheeter manages well over 20 tons. This means that we have achieved an efficiency increase of 10% with the Questec alone. However, the effect of the smart combination of the sheeters has not yet been taken into account. That is the future.

With the three sheeters, we feel really well positioned. The future is indeed an important topic for DREWSEN in many aspects - be it with new products such as drinking straws made of paper or sealable papers as a replacement for plastic bags. Sustainability is a topic close to our hearts. That's why we have just invested in three wind turbines and are planning to expand a photovoltaic footprint. As an energy-intensive company, locally produced and renewable energy plays a particularly important role for us at the moment. Our goal is to achieve climate neutrality by 2045, and we want to be 80% of the way there by 2030.

So there are many projects we are working on. The project to increase efficiency in paper converting equipment was a smaller one in comparison - nevertheless, we are very pleased with the successful implementation thanks to Questec technology and

the teamwork between everyone involved at DREWSEN and �鶹��!

Find Your Machine

�鶹�� offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the �鶹�� equipment and products offered.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)