�鶹�� offers a wide range of complete corrugators and components to meet the needs of every plant and exceed the expectations of customers. They offer customized products that meet the performance and quality requirements for different paper types, flute size, web width, production capacity and speed.

In recent years, �鶹�� has significantly grown its customer base in the EMEA region. With this growth came the need for significantly enhanced offerings for EMEA customers, not just in terms of service and after-sales support, but also reducing lead times for the supply of new equipment.

The company’s three corrugator solutions are categorized by product line as Performance, Harmony, and Value. Each line features a customizable dry-end with a range of options to align with each plant’s production and quality expectations.

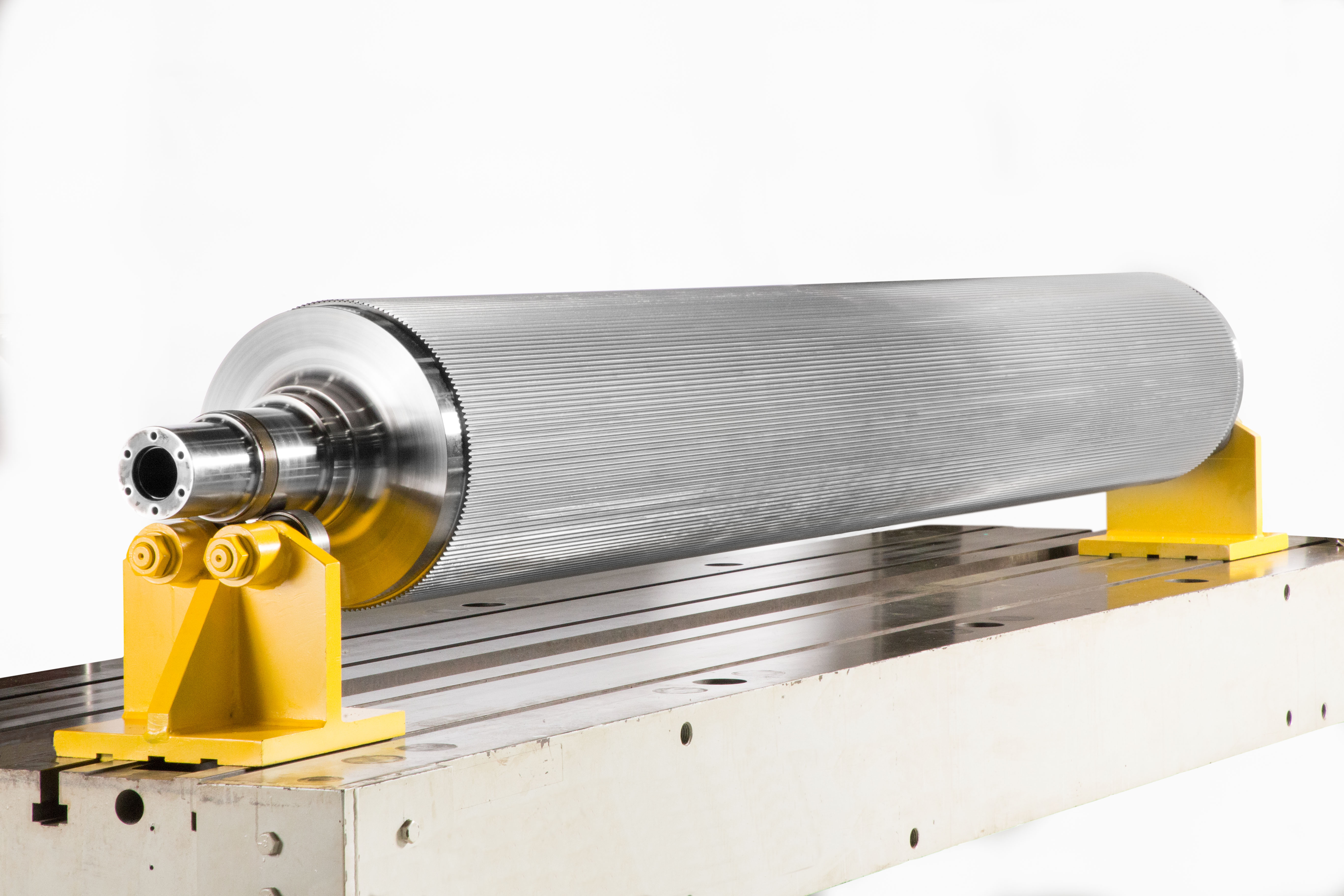

The Performance Corrugator, a legacy Marquip product, is designed for the highest board quality and production speeds. The Sentinel Corrugator process control system optimizes multiple process variables, for operators and the corrugator team. The Sentinel system features operator-friendly controls to support the production of flat, well-bonded, accurate dimensioned sheets and pre-programmed job settings alleviating unplanned downtime or slowdowns for both new and experienced operators The Sentinel control system features a waste-diverting system at the SE1000 dual rotary shear to ensure only quality product passes onto the slitter scorer. A low diverter angle improves reliability. Synchronized controls for the order change system and dynamically balanced helical-wound blades on top and bottom knife cylinders make this a great choice for many box plants. The Performance dry-end features the small footprint RPSExpress slitter-scorer. Its fast, high-precision robotic setup and plunge activation allows line speed order changes at speeds of 300 m/min. BWP’s Trim Switch eliminates trim jams at order change and allows very narrow trim to reduce waste. Setup accuracy of =/- 0.4mm ensures near-perfect adherence to specifications. The Fusion Knife and Stacker (combination), available only on the Performance corrugator, is designed to lower the total cost of ownership as the design features a 40% reduction in parts and uses a common control platform seamlessly interfaced to the corrugator process control system. The Fusion Knife and Stacker can be equipped with a splice and waste diverter to ensure only quality product is sent to the stacker tables. The Fusion Stacker can be configured as an upstacker or downstacker depending on the corrugator layout.

For more moderate demand, the Harmony Corrugator dry end is designed to work with the Excel cutoff knife, which provides excellent cut accuracy and quality with long tune intervals, high performance, and low energy consumption. The Excel and Saber knife perform industry-leading cut accuracy are available in various widths and speed versions.

The Orchestro controls systems, featured on the Harmony corrugator provide automatic setup using operator friendly

productivity boosting features and a comprehensive reporting system.

The Saber Knife, available on the Performance or Harmony dry-ends, is one of the leading industry offerings with cut length vs speed curve, and accuracy, with the capability of precision cuts up to 460 m/min. Maintenance for tuning and clearing jams is easy with walk-in access and highspeed cylinders, which provide one of the industry’s best blade turning interval cycles. The Saber Knife provides high performance with low energy consumption for increased efficiency.

Available on the Harmony Corrugator, the Excel slitter-scorer has one slit and two score sections to preset tools for the next order. At order changes, the score tools will quickly lift from the board line while new order tools lower into production. Dry-end order changes are reliable and accurate.

The Value Corrugator is reliable and cost effective and fits well in plants that have frequent order changes and a moderate demand for product output. The Value Corrugator can be configured in 1.8m, 2.2m, 2.5m and 2.85m widths with speeds from 200 m/min to 350 m/min. A premium appearance package is available to ensure the machine looks as good as it runs. The Value dry-end has a dual cylinder shear for reliable cutting and scrap removal and uses a trim cutter for single level gapless order changes. The heads of the slitter scorer have individual servo motors for accurate and fast order changes. The knife features helical wound blades with servo motor control that provides cutting accuracy of +/- 1mm. With optional single or double knife operation, the Value dry-end can be configured to handle multiple layer board. A downstacker is standard, with an optional upstacker available. The downstacker features full-width transport belts, continuous radius transport conveyor for precise shingle formation, patented speed switching for a clean load separation, reliable exact sheet counts, and optional multiple order stacking.

�鶹�� Field Service Engineers and Technical Support teams are committed to providing the best service available for installations and maintenance. �鶹�� provides on-site service and 24/7 remote troubleshooting by phone or online. For all BWP machines, training is available during installation and start up to ensure effective machine operation and efficiency. When it comes time to upgrade or replace parts, BWP provides quality OEM parts and controls necessary to ensure your equipment runs at optimal performance levels.

Machines and technology are constantly evolving, and BWP will work with customers to help reach future production

and quality goals through upgrades or improvements. �鶹�� seeks to build partnerships, and look forward

to serving every partnership for the life of every machine.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)