Knife Encoder to Resolver Conversion

Upgrade Applications

Applicable to Model I or Model II knives or any knife unit with encoders (pre-DECC*). Note: all levels must be upgraded simultaneously on multi-level knives. The Web Wheel Resolver Upgrade is recommended to be performed at the same time. Other up-grades to consider are the Web Wheel Support Pan and Web Wheel Holddown Support.Upgrade Description

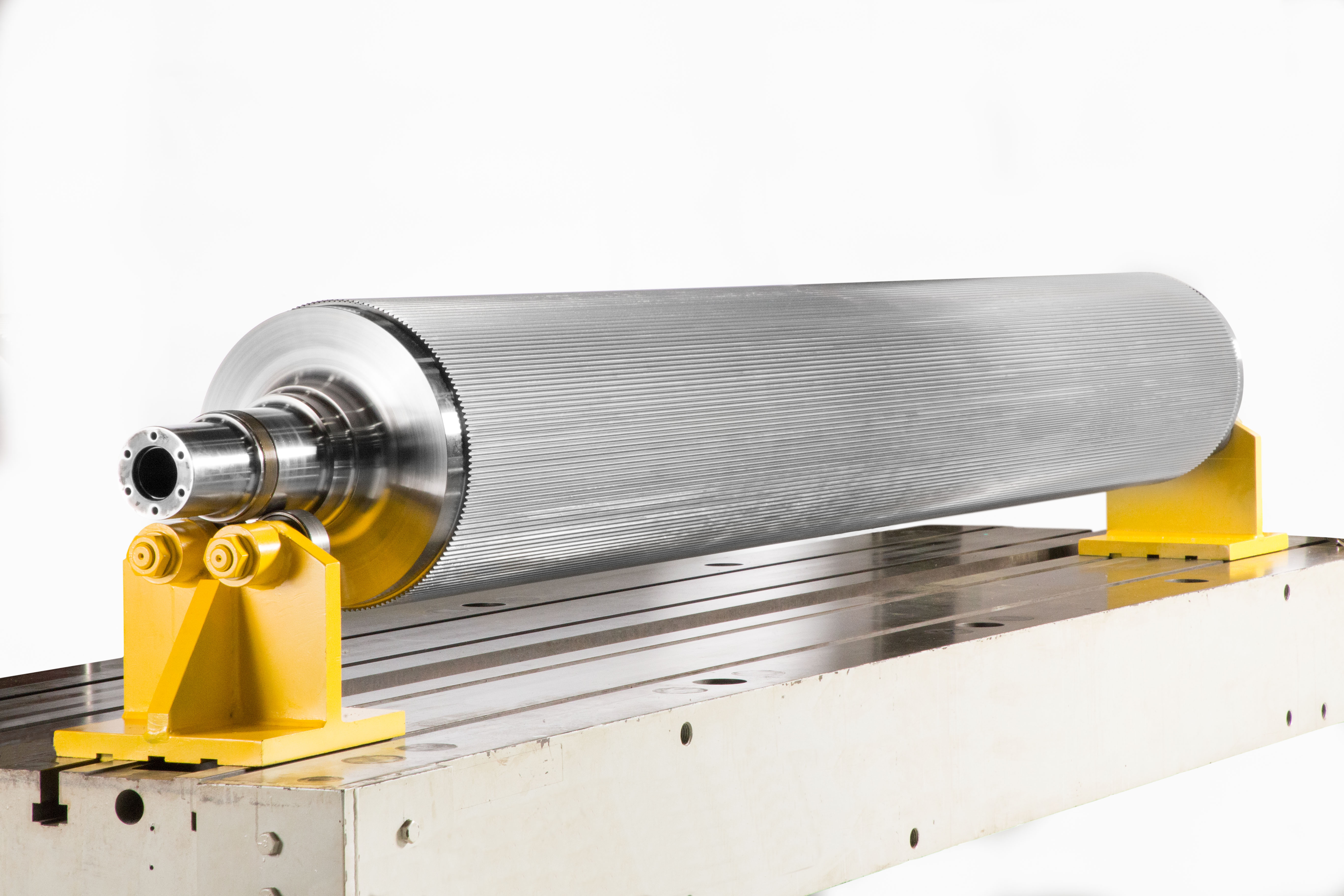

Provides conversion from encoder to resolver feedback. The pull roll, cylinder, and motor (if applicable) are replaced with resolvers. New resolver cables replace the encoder cables and resolver cards replace the encoder buffer cards.Upgrade Benefits

Large amounts of downtime occur annually due to the failure of encoder devices. Encoder failures (estimated to happen on average about 2-3 times per year) typically occur in areas involving high stress applications, such as in tracking knife cylinder position and motor commutation. Because encoders use a glass disc and internal electronics to produce positional information, they are susceptible to excess heat, vibration, and rough handling, which may result in disc breakage, electronic component failure, and electrical noise. Resolvers are much more durable than encoders, reducing the risk of cylinder control problems and/or cut length inaccuracies. In addition, electricalprocessing of the resolver positional information is done at the far end of the resolver cable, away from rough environments, further reducing the likelihood of problems typical to encoders.

*The MarquipWardUnited Dry End Cell Controller (DECC) is a control system which provides both supervisory functions and machine control for the entire dry end. The multi-processing computer architecture is housed in a single control panel for the entire dry end. DECC provides an environment for all dry end machine controls and a single operator keyboard interface station.

Technical Service

The �鶹�� Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)