Cool-Vac Doublefacer

Product Description

ΒιΆΉ΄ε is a leading manufacturer of products used by the corrugating, sheeting, and paper-converting industries. On the corrugating side, ΒιΆΉ΄ε is represented by the well-known brand MarquipWardUnited to create a full line of corrugators.

As one of the key machines in the corrugating process, ΒιΆΉ΄εβ Cool-Vac Doublefacer exceeds expectations. By eliminating crush and web weave and improving board quality, your corrugating process becomes more efficient.

Learn more about the Cool-Vac Doublefacer from ΒιΆΉ΄ε.

Cool-Vac Doublefacer Features

The Cool-Vac Doublefacer provides flat and dry corrugated sheets ready to send to converting. The sheets are ready for immediate printing, folding, gluing, and die cutting without any additional curing time. The vacuum traction section removes the excess moisture and heat from the web prior to the board entering the dry end.

The design of our doublefacer minimizes the length of the pulling section and allows the heating length to be easily configured for given space and product mix requirements.

The Cool-Vac design provides higher speeds than traditional machines for a given amount of line space. 45β (13,7m) of heating plates fits within a machine with an overall length of 63β-8β (19,4m).

Doublefacer Applications & Configurations

ΒιΆΉ΄ε understands each application of our doublefacer is different. Our expert engineering team designs machinery with your specific requirements in mind.

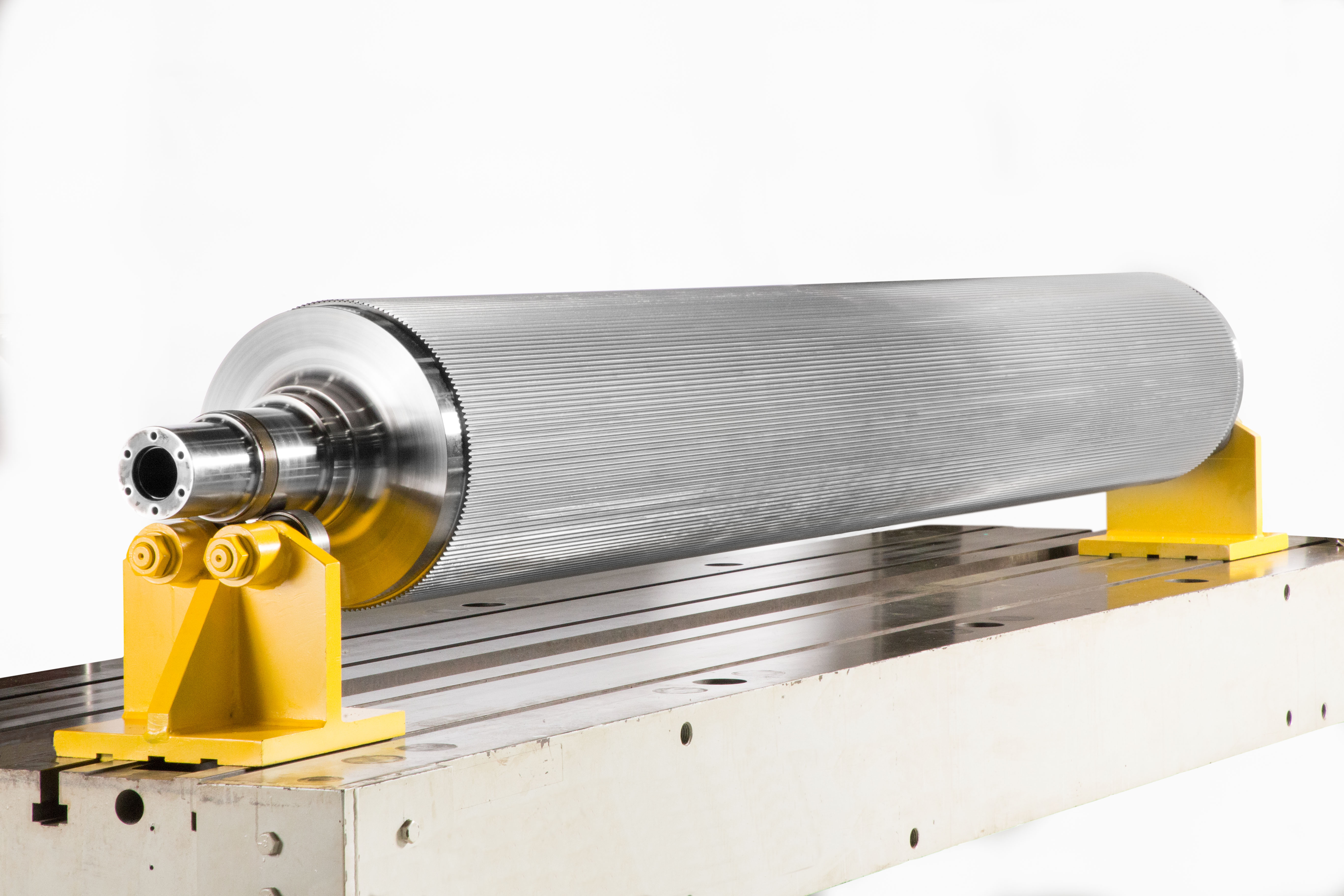

The Cool-Vac Doublefacer has two configuration options based on your application or requirements. The roller system (RS) heavy-duty doublefacer uses precise liquid-filled weight rolls for optimum heat transfer and excellent bonding.

The heat press (HP) sliding shoe systems uses a unique shoe design. It is stiff in the cross-machine direction, providing excellent bonding while eliminating board crush, especially on the edges of narrow webs.

Learn more about the technical details and benefits of these machines below.

Product Features

The Cool-Vac Doublefacer design minimizes the length of the pulling section and allows the heating length to be easily configured for given space and product mix requirements. The Cool-Vac design provides higher speeds than traditional machines for a given amount of line space.

Vacuum Traction Section

Cured Board

Gun-drilled steel hot plates

Modular Design

Machine Configurations:

Roller System (RS) Heavy-Duty Doublefacer

- The hold-down system is comprised of precise liquid-filled weight rolls.

- Roller System benefits:

- Provides even distribution of belt pressure for optimum heat transfer and excellent bonding

- The rolls do not warp. This eliminates board quality defects, even after a stop

- Weight rolls produce less drag on the belt, resulting in energy savings

- There is no need to eliminate load on the belt edges as a paper width changes. This ensures consistently good bonding across the entire web no matter how narrow the web is

Heat Press (HP) Sliding Shoe System

- The Heat Press system is a unique shoe design that is stiff in the cross-machine direction. If only a small amount of web is under the shoe, the shoe will not tilt down

- Heat Press benefits:

- Provides excellent bonding while eliminating board crush.

- Ensures superior bond at the board edges regardless of the web width.

- Eliminates the need for βoutside shoe offloading systemsβ and eliminates the belt wear associated with typical shoe systems that do not offload.

- Relatively simple system with few mechanical parts.

- Sections of hold-down can be lifted or lowered by selecting any one of a series of computer-controlled zone hold-down section versus speed curves to accommodate various board grades.

- Provides excellent bonding while eliminating board crush.

Cool-Vac Doublefacer

Compare With

- Vacuum Traction Section eliminates the possibility of board crush in the traction section. Superior traction is provided without the use of a nip to pull the board. Board caliper and stiffness are not compromised, and the highest possible caliper is preserved throughout the entire corrugating process.

- Vacuum Traction Section removes steam from the flutes, curing the board as it exits the doublefacer.

- Board that is closer to plant equilibrium can be converted at higher speed or shipped immediately to fulfill customer delivery demands.

- Gun-drilled steel hot plates virtually eliminate cupping and deflection normally experienced with conventional Doublefacers.

- Modular design allows hot plate length to be optimized for the board grades and required speeds.

- Any combination of heating sections or individual hot plates can be customer designed and built.

Find Your Machine

ΒιΆΉ΄ε offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the ΒιΆΉ΄ε equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)