G-Grafix Rotary Die Cutter

Product Description

�鶹�� is the industry-leading finishing machines supplier and our Rotary Die Cutters have a legacy of durability. The G-Grafix Corrugated Rotary Die Cutter is a robust machine designed to perform in the most demanding production environments. This Flexo Rotary Die Cutter can print and die cut sheets accurately and consistently, maximizes productivity with quick setup times, has a user-friendly interface, sturdy design and a low cost of ownership.

Contact our team of experts today to learn more.

Product Features

Ward machines are known for being productive and robust machines. Today, the rugged Ward reputation lives on as a world leader in manufacturing finishing machinery like the Rotary Die Cutter from �鶹��.

Quality

Feeders, vacuum control and full print wrap all influence the quality of the product.

Low Cost of Ownership

Productivity

Inside Printing

Making unique boxes for a stronger competitive position with inside and outside printing in a single pass.

15000 G-Grafix Rotary Die Cutter 66 in. x 113 in. | 1676 mm x 2870 mm | |||

|---|---|---|---|

| Minimum die cut sheet | 18 in. x 25.125 in. | 457 mm x 638 mm | |

| Maximum die cut sheet | 61 in. x 107.5 in. | 1549 mm x 2730 mm | |

| Sheet caliper | 0.040 in. - 0.400 in. | 1 mm – 10 mm | |

| Print image across machine | 25.125 in. – 106.75 in. | 638 mm – 2711 mm | |

| Maximum print width thru machine | 61 in. | 1549 mm | |

| Machine speed | up to 200 sheets / minute | ||

16000 G-Grafix Rotary Die Cutter 66 in. x 125 in. | 1676 mm x 3175 mm | ||

|---|---|---|

| Minimum die cut sheet | 18 in. x 25.125 in. | 457 mm x 638 mm |

| Maximum die cut sheet | 61 in. x 117.5 in. | 1549 mm x 2985 mm |

| Sheet caliper | 0.040 in. - 0.400 in. | 1 mm – 10 mm |

| Print image across machine | 25.125 in. – 118.75 in. | 638 mm – 3016 mm |

| Maximum print width thru machine | 61 in. | 1549 mm |

| Machine speed | up to 200 sheets / minute | |

G-Grafix Rotary Die Cutter

Compare With

Features of the �鶹�� G-Grafix Rotary Die Cutter

The G-Grafix Rotary Die Cutter provides superior sheet control for all calipers and grades of board including single, double, triple wall and warped board that can be problematic in other die cutters. Additionally, the G-Grafix Series Corrugated Rotary Die Cutter is one of the only machines available that will not mark micro flute board. Learn more about the Rotary Die Cutter’s specific features below.

Lead-Edge Feeder with Extended Feed

The MarquipWardUnited Extended Feed Lead-Edge Feeder combines long wearing urethane feed belts with extreme gripping characteristics, a vacuum table, low crush feed rolls and an extended stroke to provide registration and maximum sheet control while maintaining physical and aesthetic sheet quality. An optional Variable Stroke Feeder for the G-Grafix Rotary Die Cutter is available to minimize board crush.

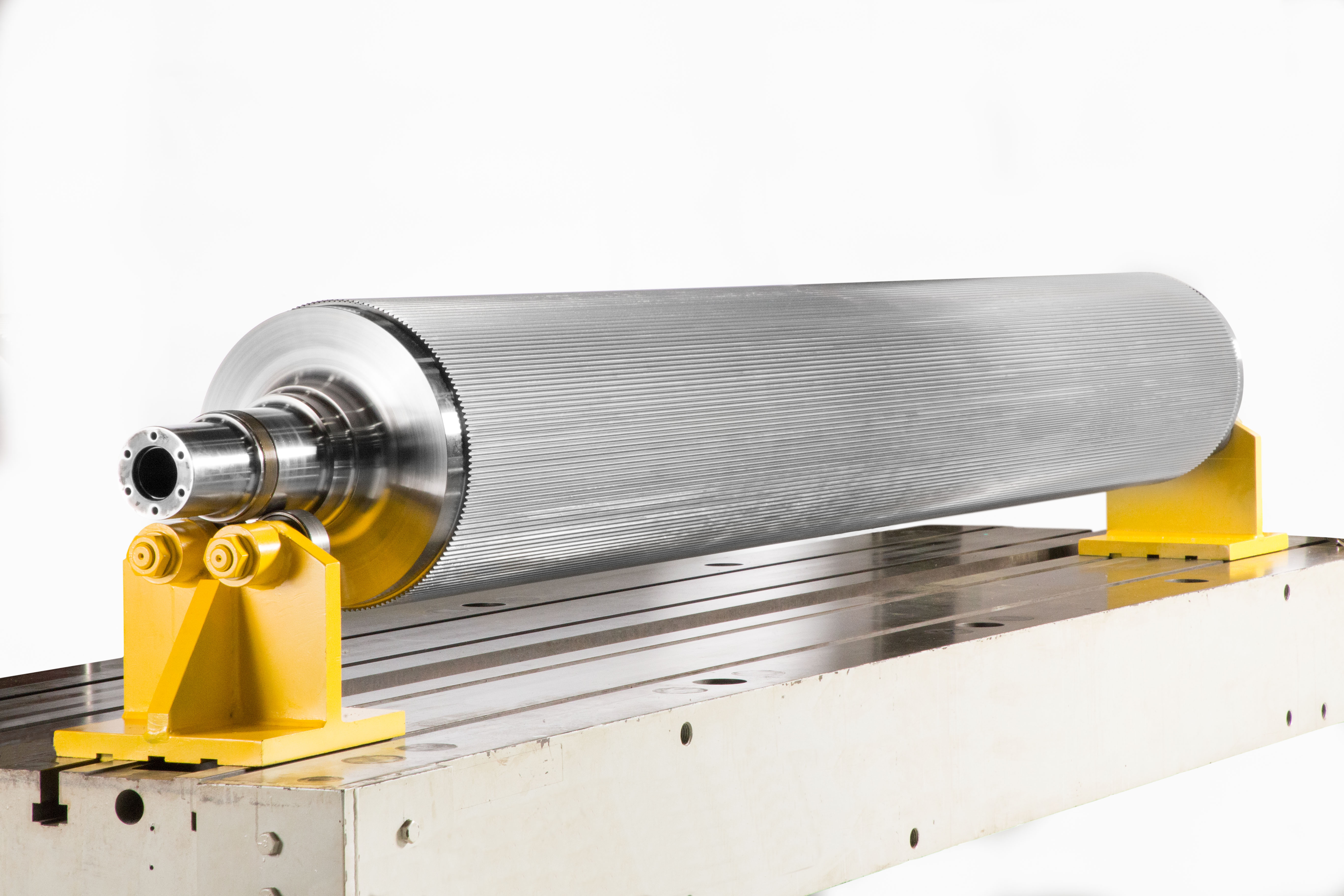

Flexographic Print Section

The G-Grafix Rotary Die Cutter’s flexographic print station provides precision control of registration by a harmonic drive register system. Impression, sheet transfer and ink metering provide the capability to print top quality, value-added process, fine screen and block work with quick and easy changeover for specific die cutting jobs.

A Legacy of Durability

The Rotary Die Cutter is the heart of the �鶹�� finishing equipment products. It is part of a line of rugged, durable and safe products that continue to offer high-quality production, reduce set-up time and maintain high expectations. The G-Grafix Rotary Die Cutter line embodies the standard of high-performance, accurate feeders, rugged rotary die cut sections and the ability to continuously handle a wide-range of product designs and configurations.

Vacuum Transfer

This vacuum transfer system of this Corrugated Rotary Die Cutter provides constant surface speed for life of the belt. This feature helps with sheet control, minimizes problems of warped board and enhances print registration. In addition, vacuum transfer maximizes rotary die production for a more efficient process.

Find Your Machine

�鶹�� offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the �鶹�� equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-machinemd.webp?Culture=en&sfvrsn=6bbc9f7f_1)